Enhance your cell innovation.

Meet the demands of OEMs with the power of Titan Silicon™. Our drop-in anode solution delivers next-generation energy density, enabling you to boost your cell performance and drive greater differentiation in your offerings.

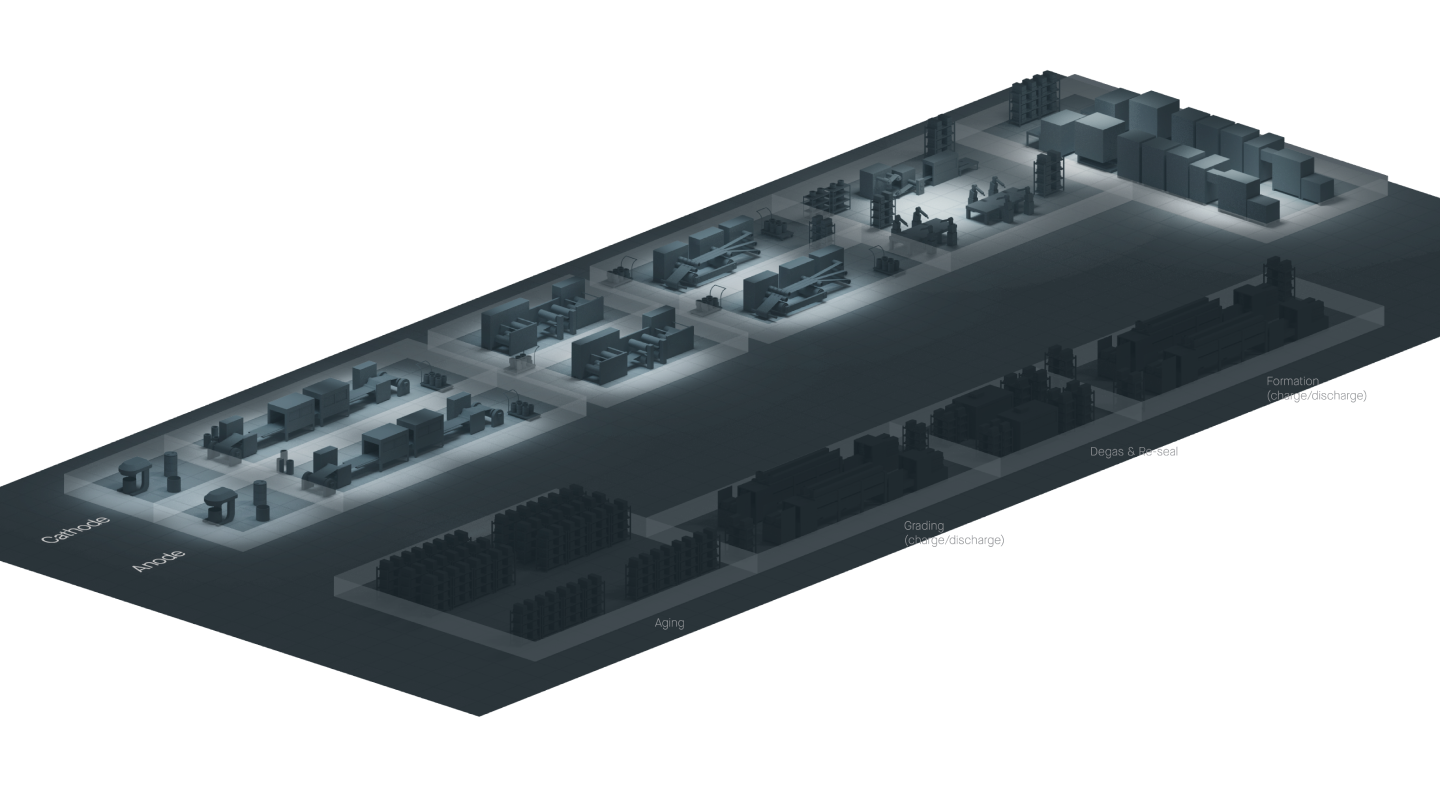

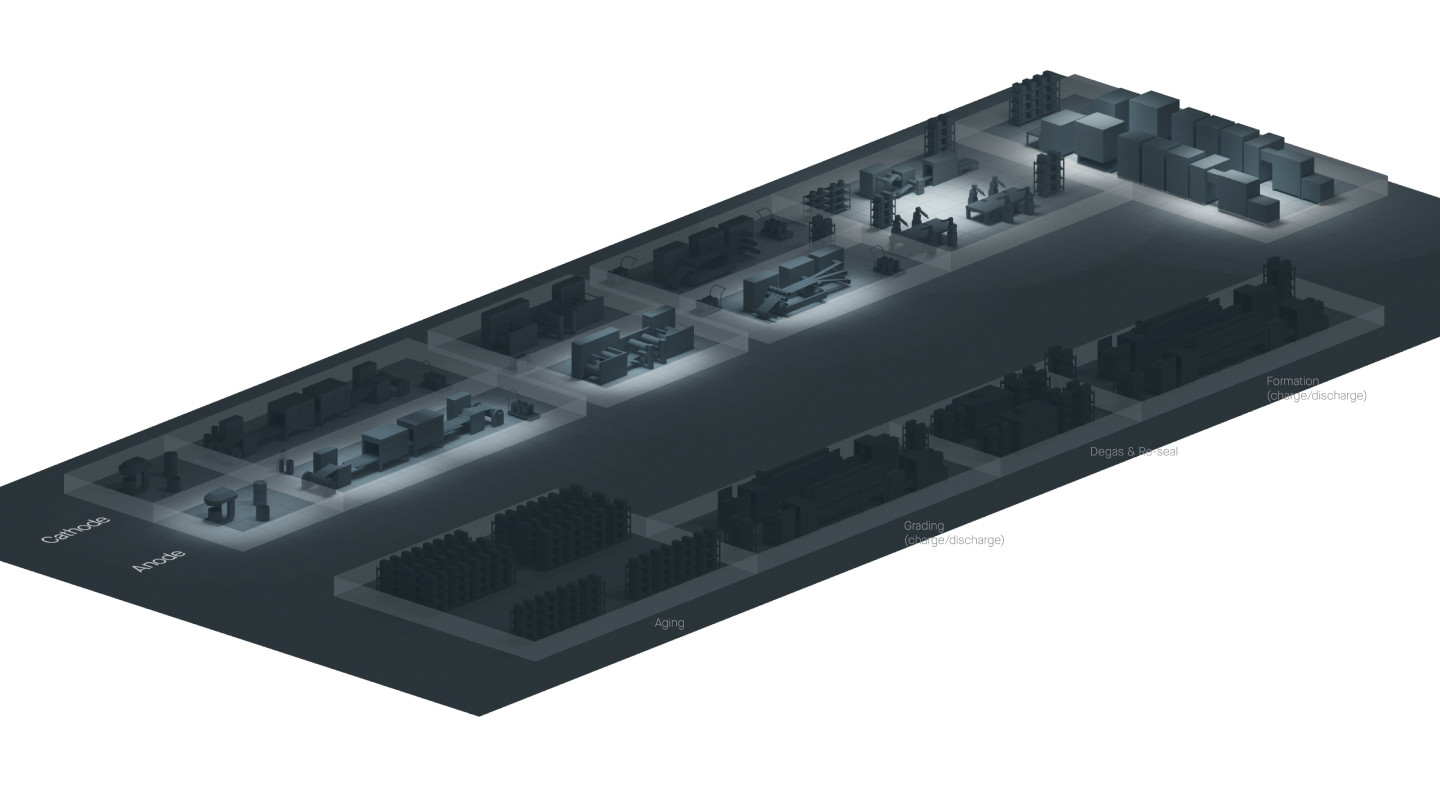

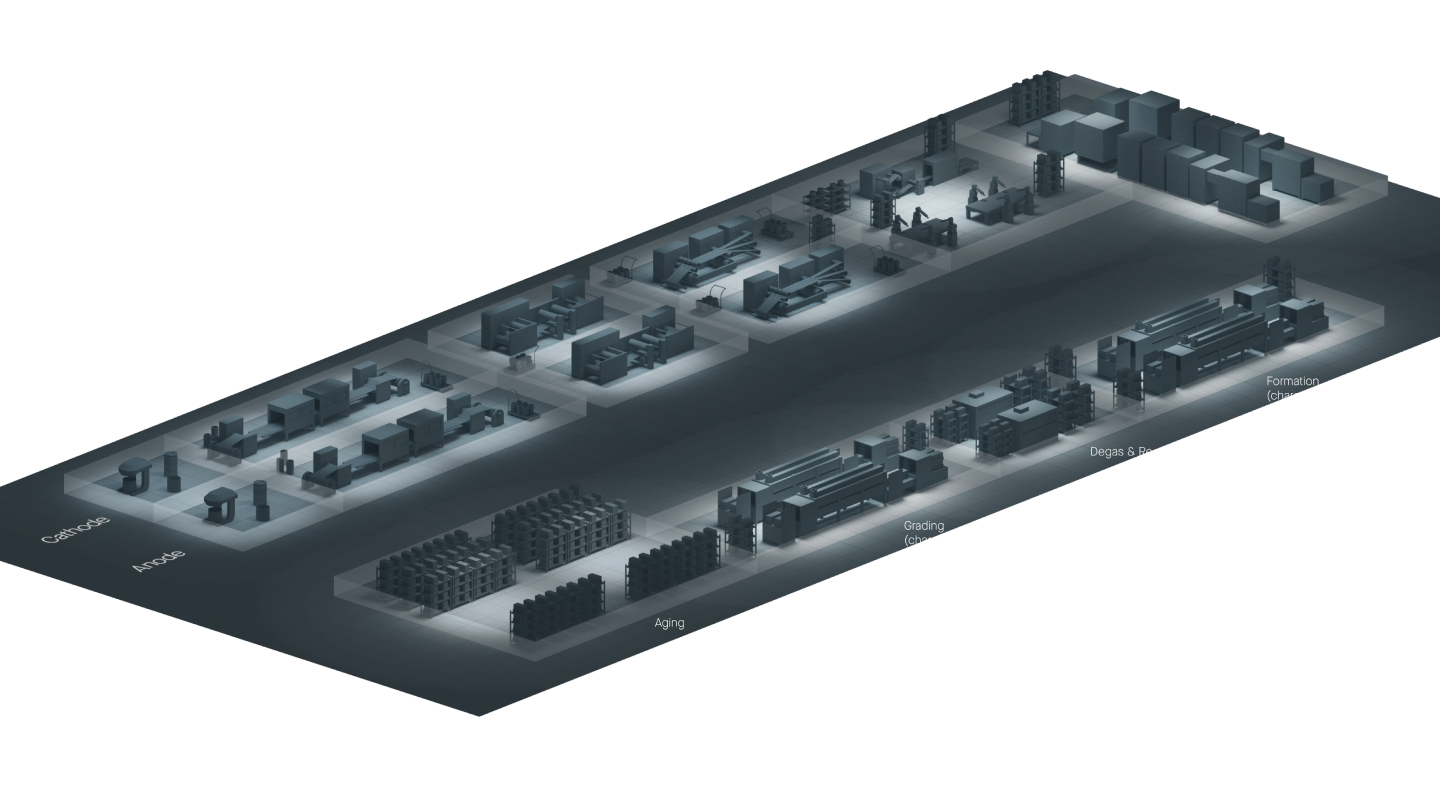

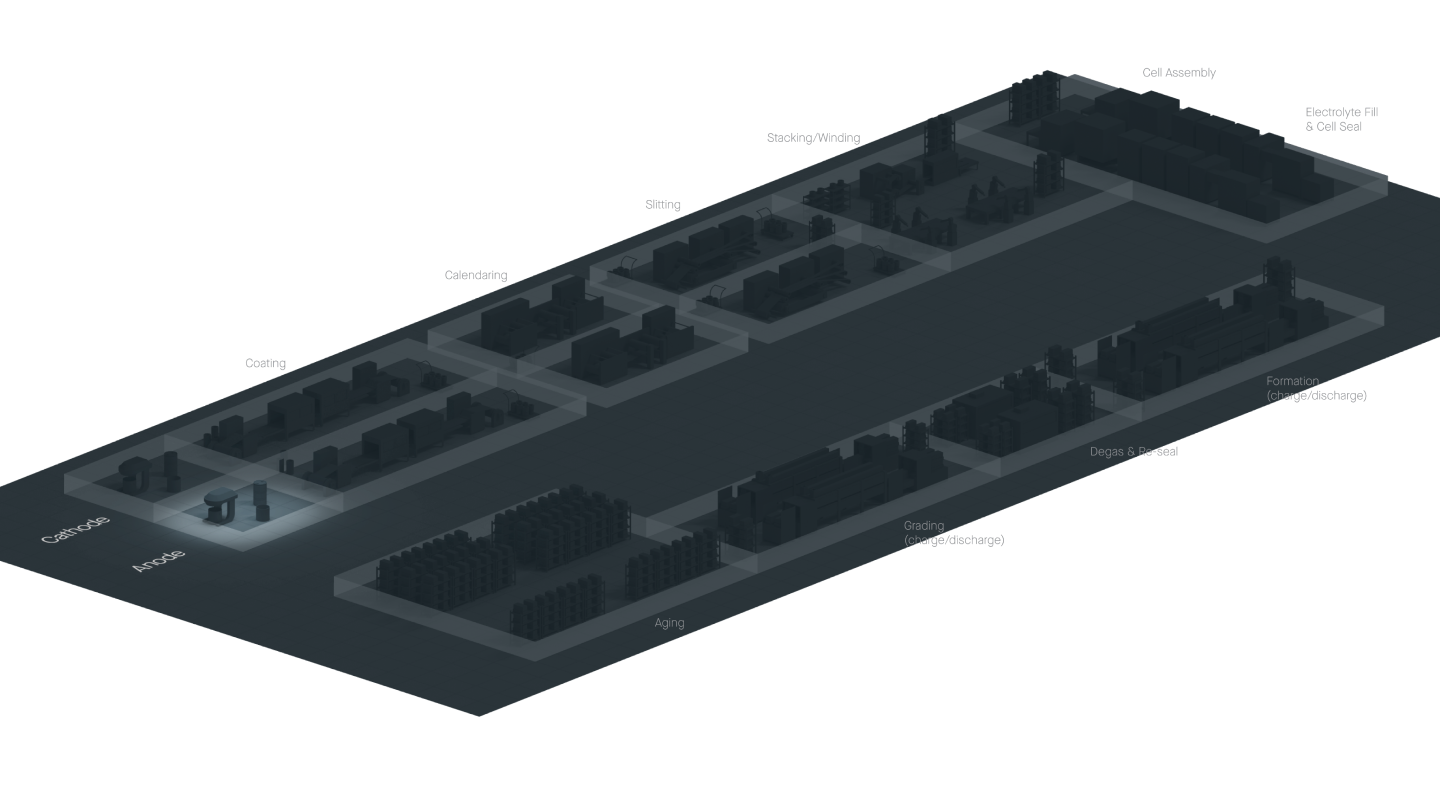

Titan Silicon slots into your factory.

Level up your output and advance your sustainability goals by changing your anode material – not your entire factory. Incorporate next-generation materials with no additional CapEx or labor.

Level up your output and advance your sustainability goals by changing your anode material – not your entire factory. Incorporate next-generation materials with no additional CapEx or labor.

Boost your output by 20%.

Increase your output with energy density gains.

Keep your same partners.

Our solutions work with any binders, additives, and cathodes you choose.

100% compatible with any cell factory.

Keep the same lines, equipment, and processes.

Lower C02 vs. graphite.

Titan Silicon generates 50-70% less CO2 per kWh than graphite during production.

Boost your output by 20%.

Increase your output with energy density gains.

Keep your same partners.

Our solutions work with any binders, additives, and cathodes you choose.

100% compatible with any cell factory.

Keep the same lines, equipment, and processes.

Lower C02 vs. graphite.

Titan Silicon generates 50-70% less CO2 per kWh than graphite during production.

Advance your battery performance

with consistent gains over time.

Legacy graphite anodes have reached their energy limit. SiOx anodes struggle to have a future. And solid state may never arrive or be relevant. Our anode technology is engineered for high energy density, delivering consistent improvements over time to match your roadmap.

Industry-leading energy density

Titan Silicon is proven in the market and safely delivers a 20% energy density increase to any lithium-ion cell today.

Robust technology for continued gains

Our novel chemistry and manufacturing will unlock a 40% energy density increase in future releases and our material is compatible with other technologies like next-generation cathodes.

Strong and broad patent protection

Our patent portfolio is robust and extensive to protect our technology

and our partners’ investments.

Solutions centered

around your cell and

customer.

Improve your cell performance without changing the way you or your OEM customers work. Our solution flexes around your customer and cell requirements with expert support to ensure launch success.

Our material drops into any lithium-ion cell and works with any OEM.

Only we offer custom material blends based on your OEM’s performance goals and roadmaps.

We provide baseline implementations for EV packs and consumer devices for faster integration.

Our battery engineering team works with you to optimize cell performance and ensure launch success.

Manufactured in the U.S.

Scaled to deliver globally.

Mass produced at the highest quality standard

Titan Silicon is being scaled to meet the demands of the market. Our solution is manufactured in the U.S. to automotive quality standards to ensure the highest level of safety and performance reliability.

U.S production for tax credit advantage

The Inflation Reduction Act offers billions in tax credits for cell makers who source material and execute production in the U.S. Working with Sila helps you get more from this opportunity.